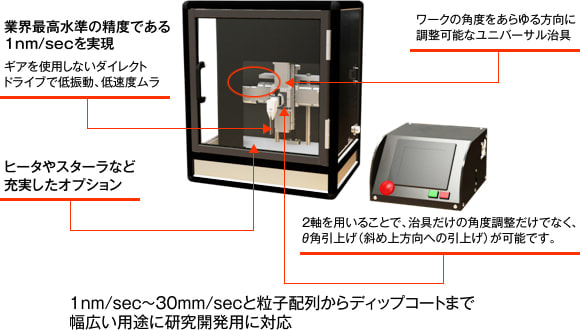

This is a series of ultra-precise pull-up speeds with a minimum speed setting of 1 nm/sec.

It can also be used for coating particle arrays and microstructures.

Dip coater N100

Model suitable for nanoparticle array, etc.

Machine cover, angle adjustment, and simple vibration isolation functions essential for dip coating at ultra-low speeds are integrated as standard so that no additional equipment is required.

| Model | N100 |

| Material of Main body | Aluminium(A505)、SUS stainless steel(SUS304)、Polypropylene |

| Material of Machine cover | Aluminium(A6N01SS-T5)、PVC(※1) |

| External Dimensions of Main body | width 290mm depth 290mm height 511mm |

| External Dimensions of Control box | width 250mm depth 285mm height 167mm |

| Weight of Main body | 12kg |

| Weight of Control box | 5kg |

| Processing speed | 1nm/sec~30mm/sec (Variable in 1nm/sec increments) |

| Processing stroke | 100mm |

| Max. workpiece weight | 500g |

| Angle adjustment(rotation) | Travel 360° Fine tuning ±5° |

| Angle adjustment(swing) | Amount of movement ±15° |

| Number of set points | 10 points |

| Number of Programs | 8 programs |

| Monitor function | Current Speed、Current Position、Remain Time |

| Other Functions | Emergency Stop、Partitive / Overall Repeat、Manual mode |

| Power supply used | 1φAC100V |

| Amount of electricity consumed | 250VA |

| Input interfaces | Touch Panel |

Dip coater N100-w

【Features】Machine cover and simple vibration isolation functions in one unit.

Machine cover and simple vibration isolation function are integrated, eliminating the need for troublesome adjustment and work.

| Model | N100-w |

| Material of Main body | Aluminium(A505)、SUS stainless steel(SUS304)、Polypropylene |

| Material of Machine cover | Aluminium(A6N01SS-T5)、PVC(※1) |

| External Dimensions of Main body | width 420mm depth 360mm height 530mm |

| External Dimensions of Control box | width 250mm depth 285mm height 167mm |

| Weight of Main body | 12kg |

| Weight of Control box | 5kg |

| Processing speed | 1nm/sec~30mm/sec (Variable in 1nm/sec increments) |

| Processing stroke | Z-axis 100mm、X-axis 100mm |

| Max. workpiece weight | 500g |

| Angle adjustment(rotation) | Travel 360° Fine tuning ±5° |

| Angle adjustment(swing) | Amount of movement ±15° |

| Machine cover | standard equipment |

| Number of set points | 10 points |

| Number of Programs | 8 programs |

| Monitor function | Current Speed、Current Position、Remain Time |

| Other Functions | Emergency Stop、Partitive / Overall Repeat、Manual mode |

| Power supply used | 1φAC100V |

| Amount of electricity consumed | 250VA |

| Input interfaces | Touch Panel |

※1 Optionally, it is possible to change to tempered glass, etc.

【Field of use】 ※Fields in bold type are those in which the product is used.

| Optical Function | Electronic Function | New Materials | Medical |

| Particle Array(Opal Membrane・Photonic Crystal) | Ferroelectric film | Foamed metal/ Porous metal | Catheters |

| Solar Cell | Insulator layer | Organic / Inorganic Hybrid Materials(Alternating Layering・Alternate Adsorption・Nanosheets) | Pharmaceutical R&D |

| Dye-sensitized solar cell、DSC | Alignment Film | Surface Hardener Coating | DNA chip (Cell culture sheet) |

| LED | Photoresist Materials | CNT | Microfluidic channels |

| Photocatalysts | LCD | Functional Ceramic Materials | Biodevice Reactor |

| Optical Lens | OLED | Non-woven fabrics | etc. |

| Optical Storage Device (CD / HDD) |

Transparent Conductive Film | Prepreg | |

| Anti-Reflection Coating | Fuel Cells | Specialty Films | |

| etc. | Hydrogen Separation Membrane | Heat Transfer Materials / Heat Dissipating Materials | |

| Nanoimprint Lithography、NIL | Filter Material | ||

| etc. | Beverage Container (PET bottle・Glass bottle) |

||

| Cutting Material | |||

| etc. |