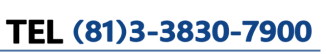

M200S-Y

As with conventional equipment, sequences are input using a touch panel. No special programming knowledge is required. The speed range can be controlled from 0.1 µm/sec, and can be used for particle sequencing.

In contrast to conventional dry process thin film production, which requires a vacuum chamber, the wet process enables low-cost film formation at room temperature and pressure.

The Alternate Adsorption method (Alternating Layering method, Layer By Layer) can control film thickness on the nanometer order and can be expanded to mass production in the future, such as roll-to-roll method. This system emphasizes reproducibility, and various conditions can be set for testing and research purposes for mass production.

It also has a regular dip coat mode and can be used as a stand-alone dip coater.

| Model | M200S-Y | |

| External Dimensions of Main body(mm) | Main body | W300 × D350 × H700 |

| Control Box | W310 × D285 × H167 | |

| Index Table | W200 × D206 × H186 ※1 | |

| Material of Main body | SUS304、A5052P、PP | |

| Processing speed | 0.1μm/sec~20mm/sec Variable in 0.1μm/sec increments | |

| Processing stroke | 200mm | |

| Workpiece size | When used as an Dipcoater | Max H200 × W200 |

| When used as an Index Table | Max H50 × W25 | |

| Max. workpiece weight | 1kg | |

| Number of beakers that can be installed | 8 pieces | |

| Power supply used | AC100V 400VA | |

| Option | Machine cover / Antivibration Table | |

※1 Includes beaker size

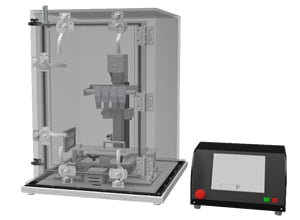

F225-LBL

Multiple sheets can be processed at the same time. Gas displacement reduces volatilization of the coating liquid, making it possible to handle coating for long periods of time.

| Model | F225-LBL | |

| External Dimensions of Main body(mm) | Main body | W540 × D600 × H730 |

| Control Box | W360 × D285 × H220 | |

| Material of Main body | SUS304、A5052P、PP | |

| Processing speed | 0.1mm/sec~30mm/sec Variable in 0.1mm/sec increments | |

| Processing stroke | 225mm | |

| Workpiece size | W25 × H25~35、t2mm(4 at the same time) | |

| Max. workpiece weight | 1kg | |

| Number of beakers that can be installed | ||

| Power supply used | AC100V 350VA | |

| Machine cover | Gas displacement specification(Positive pressure safety valve included) | |

| Option | Antivibration Table | |

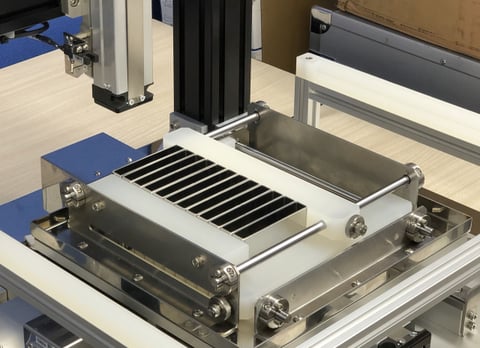

F225-LBL12

Based on the F225-LBL, the F225-LBL is a system with more tanks that can be set to process multiple coating liquids at the same time.

| Model | F225-LBL12(Max. 24 tanks can be set) | |

| External Dimensions of Main body(mm) | Main body | W540 × D520 × H647.5 |

| Control Box | W360 × D285 × H220 | |

| Material of Main body | SUS304、A5052P、PP | |

| Processing speed | 0.1mm/sec~50mm/sec Variable in 0.1mm/sec increments | |

| Processing stroke | 225mm | |

| Workpiece size | W25 × H76、t2mm (4 at the same time) | |

| Max. workpiece weight | 500g / piece | |

| Number of beakers that can be installed |

24 pieces(12 pieces 2 rows) | |

| Power supply used | AC100V 350VA | |

| Option | Antivibration Table | |