M215-Advanced

This model is capable of automatic control of Z-axis and θ-axis. Manual mode is also provided for each axis for easy operation.

The interface is also an easy-to-configure PC-based touch panel large screen, eliminating the need to switch input screens.

| Model | M215-Advanced |

| Material of Main body | Aluminium(A505)、SUS stainless steel(SUS304) |

| Material of Jig | Polypropylene(PP) |

| External Dimensions of Main body | width 400mm depth 300mm height 503~758mm |

| Weight of Main body | 13kg |

| Processing speed | 1μm/sec~40mm/sec (Variable in 1μm/sec increments) |

| Processing stroke | 215mm |

| Max. workpiece weight | 1kg |

| Angle adjustment | Automatic Controls |

| Machine cover | Option |

| Number of set points | 10 points |

| Number of Programs | 8 programs |

| Operation Monitor | Current Speed、Current Position、Remain Time、Remaining count |

| Other Functions |

|

| Power supply used | 1φAC100V |

| Amount of electricity consumed | 250VA |

| Input interfaces | Touch Panel |

| Option | Manual rotation mechanism for θ angle、Auto rotation mechanism for θ angle |

F525S-Y

Without the use of gears, etc., a wide speed range of 1μm/sec to 300mm/sec can be covered by a single unit to meet a wide range of needs.

| Model | F525S-Y |

| Material of Main body | Aluminium(A505)、SUS stainless steel(SUS304) |

| Material of Jig | SUS stainless steel(SUS304) |

| External Dimensions of Main body | Main body: width 600mm depth 400mm height 1340mm Control box: width 300mm depth 300mm height 295mm |

| Weight of Main body | Main body: 25kg |

| Processing speed | 1μ/sec~300mm/sec (Mode switchable) |

| Processing stroke | 525mm |

| Max. workpiece weight | 5kg |

| Machine cover | Option |

| Number of set points | 10 points |

| Number of Programs | 82 programs |

| Other Functions | Emergency Stop、Partitive / Overall Repeat、Manual mode |

| Power supply used | 1φAC100V |

| Amount of electricity consumed | 250VA |

| Input interfaces | Touch Panel |

F1000S

This equipment is designed to dip coat large 1m square workpieces. Jigs for heavy workpieces, prevention of the main body from tipping over, and safety measures are provided.

| Model | F1000S |

| Material of Main body | Aluminium(A505)、SUS stainless steel(SUS304) |

| Material of Jig | SUS stainless steel(SUS304) |

| External Dimensions of Main body | Main body: width 1620mm depth 1280mm height 2860mm Control box: width 410mm depth 325mm height 220mm |

| Weight of Main body | Main body:100kg |

| Processing speed | 0.1mm/sec~50mm/sec |

| Processing stroke | 1000mm |

| Max. workpiece weight | 30kg |

| Machine cover | Option |

| Number of set points | 15 points |

| Number of Programs | 20 programs |

| Other Functions | Emergency Stop、Partitive / Overall Repeat、Manual mode |

| Power supply used | 3φ200V |

| Amount of electricity consumed | 1kVA |

| Input interfaces | Touch Panel |

F400L

Precision dip coater [Linear mode]

| Model | F400L |

| Material of Main body | SUS stainless steel(SUS304)/ A5052P |

| Material of jig | SUS stainless steel(SUS304) |

| External Dimensions of Main body | Main body:width 500mm depth 400 height 1100mm |

| Control Box:width 310mm depth 285 height 167mm | |

| Weight of Main body | 22kg |

| Number of sheets processed | one sheet |

| Processing speed | 0.1mm/s~200mm/s (Variable in 0.1mm/sec increments) |

| Processing stroke | 400mm |

| Machine cover | Option |

| Stop position | 0mm~400mm (Variable in 0.1mm increments) |

| Stopping time | 0.1sec~999.9sec (Variable in 0.1sec increments) |

| Number of repetitions | 1 to 998 times (Can be changed in one-time increments.) ※If set to 999 times, it will continue to operate continuously. Repeatable operation at each point(Full/partial cutover) |

| Number of set points | 10 points |

| Number of Programs | 8 programs |

| Operation Monitor | Current Speed、Current Position、Remain Time、Remaining count |

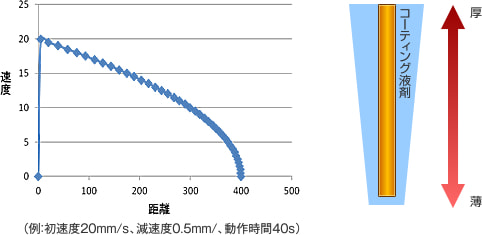

| Input items at Linear-DIP | Initial velocity、Initial velocity、Traveling time、Travel distance |

| Initial velocity at Linear-DIP | 0.1mm/s~200mm/s (Variable in 0.1mm/sec increments) |

| Deceleration ratio at Linear-DIP | 0.1mm/s2~200mm/s2 (Variable in 0.1mm/s2 increments) |

| Input interfaces | Touch Panel |

| Power supply used | AC100V |

| Amount of electricity consumed | 250VA |

Simulator equipment for R&D

It is a device to simulate various batch processes in a clean environment without human intervention.

The main robot is a movable six-axis robot, which performs fully automated processes such as agitation and heat treatment from workpiece input to discharge, enabling more precise quantification of the calculation of conditions for automation. Each process can be combined with existing equipment, enabling introduction at a lower cost.