Dip coating utilizes the relationship between the surface tension of a coated material and coating liquid, so the process of cleaning the surface of a coated material is indispensable.

If the surface of a coated material is contaminated, film properties such as wettability and adhesion may be significantly reduced.

If the cleaning and dip coating processes are separated into separate equipment, there is a risk of recontamination after cleaning, so an integrated equipment configuration is recommended for mass production equipment.

For cleaning methods, we can propose the most appropriate method, ranging from dry cleaning to wet cleaning.

Dry Cleaning

Pretreatment for dip coating is divided into wet cleaning (wet process) and dry cleaning (dry process), including UV ozone cleaning, plasma cleaning, and ultrasonic cleaning.

In this article, we will explain UV ozone cleaning, which is one of the simplest and easiest to introduce.

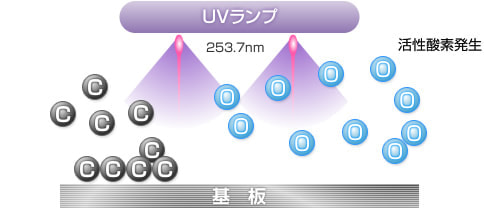

In UV ozone cleaning, at first, short-wavelength ultraviolet (UV) light energy emitted from UV lamps (low-pressure mercury lamps) breaks down organic contaminant bonds on the surface of a coated material.

At this time, oxygen molecules (O2) are also decomposed to generated oxygen atoms (O). The generated oxygen atoms are converted to ozone (O3) and then to active oxygen (O-).

The generated active oxygen (O-) combines with a decomposed organic contaminant, and eventually the surface of a coated material is cleaned of the organic contaminants.

Mechanism of surface cleaning and modification by UV irradiation

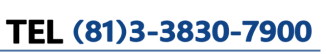

1) Before cleaning treatment

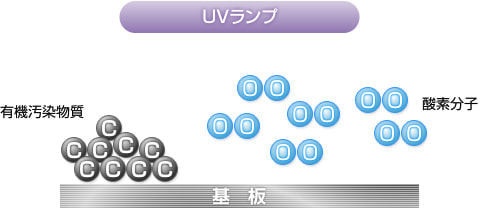

2) UV irradiation

The bonds of organic contaminant are decomposed by ultraviolet rays at a wavelength of 184.9 nm emitted from the UV lamps. Oxygen molecules (O2) are also decomposed to generate oxygen atoms (O).

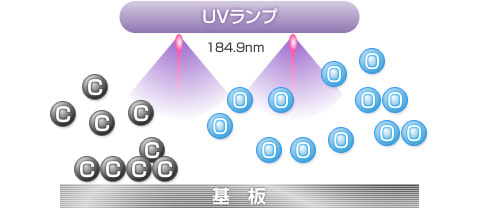

3)Generation of ozone

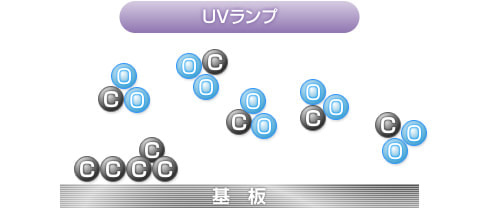

Decomposed oxygen atoms (O) combine with oxygen molecules (O2) in the atmosphere to generate ozone (O3).

4) Generation of active oxygen

When the generated ozone (O3) is irradiated with ultraviolet rays at a wavelength of 253.7 nm, ozone is decomposed to generate active oxygen (O-).

5) Elimination of contaminants

The process 2) to 4) are repeated simultaneously, resulting in a state rich in active oxygen (O-). The active oxygen generated combines with carbon (C), which is a contaminant on the substrate, to converted to carbon dioxide (CO2), which is then eliminated.

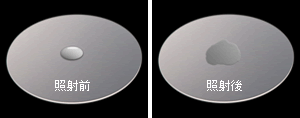

Case studies: Surface Cleaning Modification

About wet cleaning

In the wet cleaning process, we proposal for the best cleaning systems for various environments, including water/pure water, organic solvent, and hydrocarbon -based.

Adhesion under the same coating and curing conditions

Coating film peeling can be noticeable on a coated material in case without wet washing.

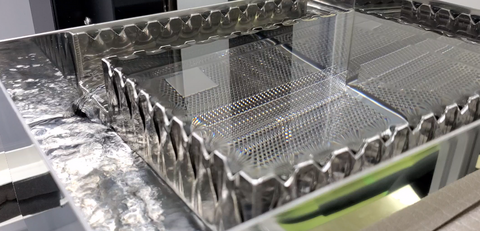

Case studies: Water-based cleaning equipment

By performing oscillating and ultrasonic cleaning with city water or pure water before dip coating, contamination is removed and adhesion of coating liquid is improved.