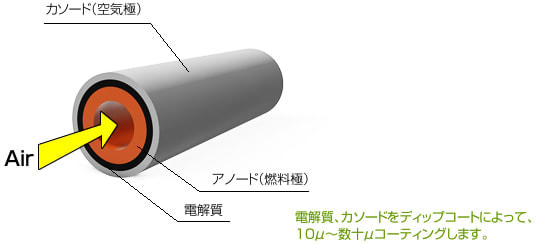

About coating for “Microtubular Solid Oxide Fuel Cells (SOFC)”

Recently, as a countermeasure against global warming, the development of new energy sources to replace petroleum has been called for.

In particular,” Fuel-Cells” are expected from various fields as a next-generation clean energy source whose products are water and heat.

Among them, Solid Oxide Fuel Cells (SOFC) are said to be the ultimate fuel cells and have the following outstanding characteristics.

- The operating temperature is high, the electrode reaction proceeds smoothly, and irreversible losses are small, resulting in high power generation efficiency. Also, expensive precious metals are not required as electrocatalysts.

- The waste heat is of high value because of the high temperature at which it is discharged.

- Oxide ions (oxygen ions) are transported from the air electrode (cathode) to the fuel electrode (anode) via the electrolyte, allowing a wide range of fuel types to be used.

Solid Oxide Fuel Cells (SOFC), which have many advantages, are expected to become the mainstream of stationary Fuel Cells once they are put into practical use.

On the other hand, its development requires that the coating film be as thin as possible because solid oxide electrolytes have low ionic conductivity.

Solid thin films are prone to cracks and pores, and Solid Oxide Fuel cells (SOFCs), which are subject to high temperatures, require high-precision dip coating equipment for electrolyte and other coatings.

[Reference report] Report on the use of our equipment by the Graduate School of Engineering, The University of Tokyo

For dip coaters, please contact our Sales Engineering Department.